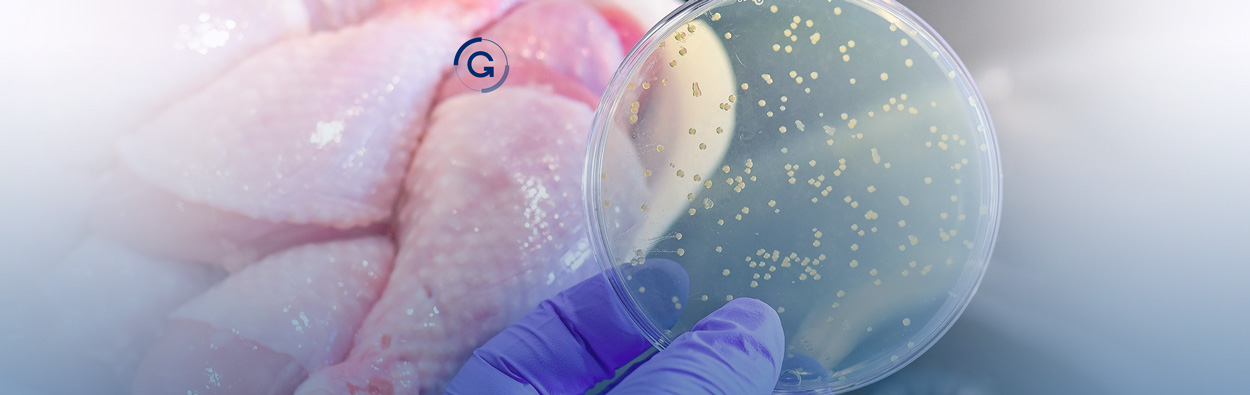

Salmonella Contamination in Chicken

Nov 14, 2024

Chicken is a popular food worldwide due to its high protein, lipid, vitamin, and mineral content, including calcium, iron, zinc, potassium, and magnesium. It is easily digestible and suitable for a wide range of people. However, there is a significant risk of contamination throughout the manufacturing process.

In this blog, we will discuss the primary stages of the manufacturing and handling procedures in which the product may become contaminated. We will also review the actions that can be taken to prevent harm to the consumer's health.

Being slaughter of poultry the first handling step, the stages of this process are as follow:

- Reception of poultry: Live chickens are received after the fattening phase, while avoiding high temperatures that could lead to heat death.

- Slaughter and plucking: Live animals are transported to the slaughter area, where they are hung and bled using knives and specialized equipment. After bleeding, they go through the process of plucking and having their legs cut.

- Evisceration line: The removal of viscera, head-cutting, and sewer extraction take place.

- Draining and packing: The animals move to the draining and packing line, where the internal cleanliness of the chickens is examined, and a selection is made based on size. Finally, the chickens are packaged, either whole or processed.

![]()

But where exactly in the process is the product susceptible to contamination?

- During electric stunning, the relaxation of sphincters can cause fecal matter to exit and contaminate the animal's body surface with enteric microorganisms such as Salmonella.

- Microorganisms can be spread from one animal to another during bleeding through the blade of the knife or device used.

- There is a risk of cross-contamination during plucking when fecal germs from the skin, feathers, and dirt can contaminate the surface. This stage poses the highest risk of contamination from microorganisms such as Pseudomonas, Clostridium, Campylobacter spp, E. coli, and Salmonella.

- Direct contact with the hands of the workers or the evisceration equipment during evisceration can lead to cross-contamination between the carcasses.

![]()

Food contaminated with Salmonella or other enteric microorganisms may appear, taste, and smell normal, making it difficult to detect contamination with the naked eye. Therefore, it is crucial to take preventive measures.

The primary symptoms of salmonellosis include diarrhea, fever, and abdominal cramps that typically begin 12 to 72 hours after consuming contaminated food. Symptoms usually last for about 4 to 7 days, and most people recover without requiring drug treatment. However, some cases may require hospitalization, as Salmonella infection can spread from the intestines to the bloodstream and cause death.

It is estimated that for every laboratory-confirmed case of Salmonella disease, nearly 30 other cases go unreported. As most people do not seek medical attention for these symptoms, it is impossible to have accurate data. However, the CDC estimates that Salmonella causes over 1 million foodborne illnesses in the United States annually.

"If the chicken becomes contaminated during production, what actions can the food service sector take to eliminate enteric bacteria during preparation?"

- Ensure that the internal temperature of the chicken reaches 165°F when cooking.

- Keep raw chicken and its juices physically separate from ready-to-eat foods, such as salads or other cooked foods.

- Avoid washing raw chicken as chicken juices can spread in the kitchen and contaminate other foods and utensils.

- Establish a color code for utensils to distinguish between different types of food, including fruits and vegetables, meats, poultry, fish, seafood, and eggs.

- Use different utensils for raw and cooked foods.

- Use hot water and soap to wash dishes and utensils that were in contact with raw beef, turkey, seafood, and eggs.

- Keep food warm (140°F or higher) after cooking and monitor the temperature of cold rooms, refrigerators, and freezers using calibrated instruments to prevent bacteria from developing in the danger zone between 40°F and 140°F."

![]()

These measures are based on scientific research in both academic and industrial fields and have been mandated by authorities for implementation in restaurants, food manufactures, and households. If you own a place where chicken is handled, please contact us for expert advice on the best practices for handling these products tailored to your specific needs.

Rebeca Macazaga Álvarez, Master in Biological Sciences.

“I collaborate in the Restaurants team in the development operating procedures for companies that want to implement HACCP systems. I have experience in the food safety area since 2008, in hazard analysis, training, implementation, and second-party audits.”

Raw Milk Recall Due to E. coli Contamination

Emergent Cantaloupe Recall and Salmonella Outbreak in North America

Alarming Surge in Salmonella: Critical Cantaloupe Recall and Urgent Food Safety Measures

Join our Food

Safety Community!

Stay ahead of the curve by exploring emerging

trends and technologies in food safety.