What is a Preventive Control Plan (PCP) in Canada?

Nov 14, 2024

For food manufacturers in Canada, ensuring the safety of their products is paramount. The Canadian Food Inspection Agency (CFIA) plays a vital role in safeguarding the food supply chain, and one of the key tools they utilize is the Safe Food for Canadians Regulations (SFCR). This set of regulations outlines the requirements for ensuring food safety throughout the food chain, from farm to fork.

Why are Preventive Control Plans Important?

A cornerstone of the SFCR is the requirement for certain food businesses to establish, implement, and maintain a Preventive Control Plan (PCP). A PCP serves as a documented roadmap outlining the strategies a food business employs to identify and mitigate potential hazards associated with their food products. By proactively identifying and addressing these hazards, food manufacturers can significantly reduce the risk of foodborne illness outbreaks.

What Does a PCP Entail?

The SFCR mandates that a PCP encompasses several key elements:

- Hazard Identification: The first step involves conducting a thorough hazard analysis to pinpoint all potential biological, chemical, and physical hazards that could contaminate food products at any stage of the production process.

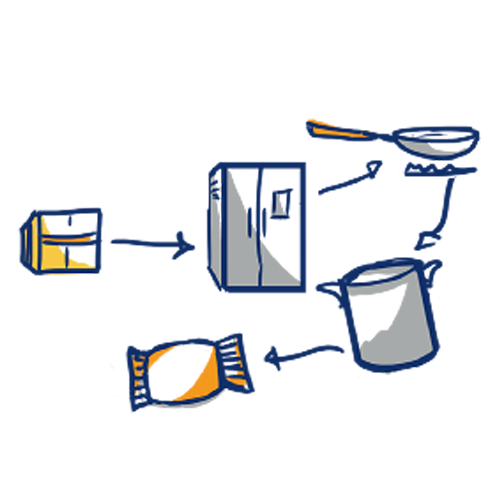

- Preventive Controls: Once hazards are identified, the PCP must detail the specific control measures that will be implemented to eliminate or reduce these hazards to an acceptable level. Examples of control measures could include proper sanitation procedures, temperature control during storage and transportation, and rigorous allergen management protocols.

- Monitoring Procedures: The PCP needs to outline the monitoring procedures that will be used to verify the effectiveness of the implemented control measures. This may involve monitoring critical control points (CCPs) within the production process, where a loss of control could result in a food safety hazard.

- Corrective Actions: The PCP must establish a plan for corrective actions that will be taken when monitoring activities reveal deviations from established control parameters. This plan should detail how identified issues will be addressed and prevented from recurring.

- Verification: Regularly scheduled verification activities, such as internal audits and third-party inspections, are crucial to ensure the overall effectiveness of the PCP. Verification activities help identify any gaps or weaknesses in the plan and ensure continuous improvement.

Benefits of a Robust PCP

Implementing a comprehensive PCP offers numerous benefits for food manufacturers:

- Enhanced Food Safety: A well-designed PCP minimizes the risk of foodborne illness outbreaks, protecting consumers and safeguarding public health.

- Improved Regulatory Compliance: A documented PCP demonstrates a commitment to food safety and facilitates compliance with the SFCR requirements.

- Strengthened Brand Reputation: Consumers increasingly prioritize food safety. A robust PCP fosters trust and strengthens a manufacturer's brand reputation.

- Reduced Risk of Product Recalls: By proactively addressing potential hazards, the risk of costly product recalls is significantly reduced.

Get Expert Help with Your PCP

Developing and maintaining a compliant and effective PCP requires expertise in food safety regulations and best practices. GoHACCP with Experts provides a team of experienced food safety consultants who can assist food manufacturers in Canada with all aspects of PCP development, implementation, and ongoing maintenance.

Stay Ahead of the Curve with GoHACCP with Experts

Sign up for our newsletter to receive regular updates on the latest food safety regulations, industry trends, and best practices. By staying informed, you can ensure your food business remains compliant and continues to deliver safe, high-quality products to consumers.

Contact GoHACCP with Experts today to learn more about how we can help you develop and implement a robust PCP that safeguards your food products and your business.

Nahomy Garcia, B.Sc.

“I currently work as a food safety expert in the HACCP department of the company. I am in charge, together with my team, of developing food safety plans such as HACCP and PC plans under FDA, CFIA, or USDA/FSIS regulations to achieve food certification projects for our clients.”

16 infected due to California’s Raw Farms LLC Recall: What You Need to Know to Prevent Outbreaks

Understanding the Listeria Plan in USDA: Safeguarding Food from a Silent Threat

Assessing the Effectiveness of Your HACCP Plan: A Year Later

Join our Food

Safety Community!

Stay ahead of the curve by exploring emerging

trends and technologies in food safety.