What is HACCP?

Nov 14, 2024

We have all heard the term HACCP, but few of us have questioned what it is, what its function is, and what characteristics describe it. Within these lines, we will explain simply that a well-constituted HACCP Plan is based on its 7 principles whose purpose will always be to safeguard the integrity of the final product through.

A HACCP Plan is a set of analysis and control of biological, chemical, and physical risks in various food processing systems or products for human consumption that is managed through good manufacturing practices.

A HACCP Plan can be designed for suppliers seeking to implement a Food Safety Program, Supplier with a Food Safety Program already in place, Certification Body Representative, Food Safety Services Provider, Foodservice Professional, Government and/or Economic Development Professional, Retailer and Wholesalers, Auditor or Consultant, Students, and Training Center Representative.

The proper implementation of a HACCP Plan helps reduce the likelihood of customer complaints or a recall by identifying and controlling potential hazards from raw materials, facility processes, and human error. In addition, the greater awareness that results from a HACCP Program helps to drive continual improvement of a company’s products and processes.

Food industry standards increase year after year, exceeding the regulatory requirements due to the golden rule of "consumers’ health is never compromised by consuming adequate food.” For companies, achieving food safety brings positive results like ensuring business continuity and success by guaranteeing products of the best quality, regulatory compliance, and brand protection. In addition, food safety generates a new degree of confidence for consumers, chambers of commerce, and government agencies.

Establishing the HACCP Plan helps companies effectively detect and prevent safety risks in production and compliance with legal requirements for food safety. The recognition of the HACCP Plan as the most effective method in safety control has positioned it as one of the most widely adopted methodologies in various countries such as the USA, Canada, Japan, Australia, and the European Union. As a result, the HACCP plan has established itself as an essential requirement for the commercialization of products. Furthermore, over time the HACCP Plan has been increasing followers. Hence, it is necessary to regulate it in many countries and required in various areas of the food industry.

But how is a HACCP Plan consolidated?

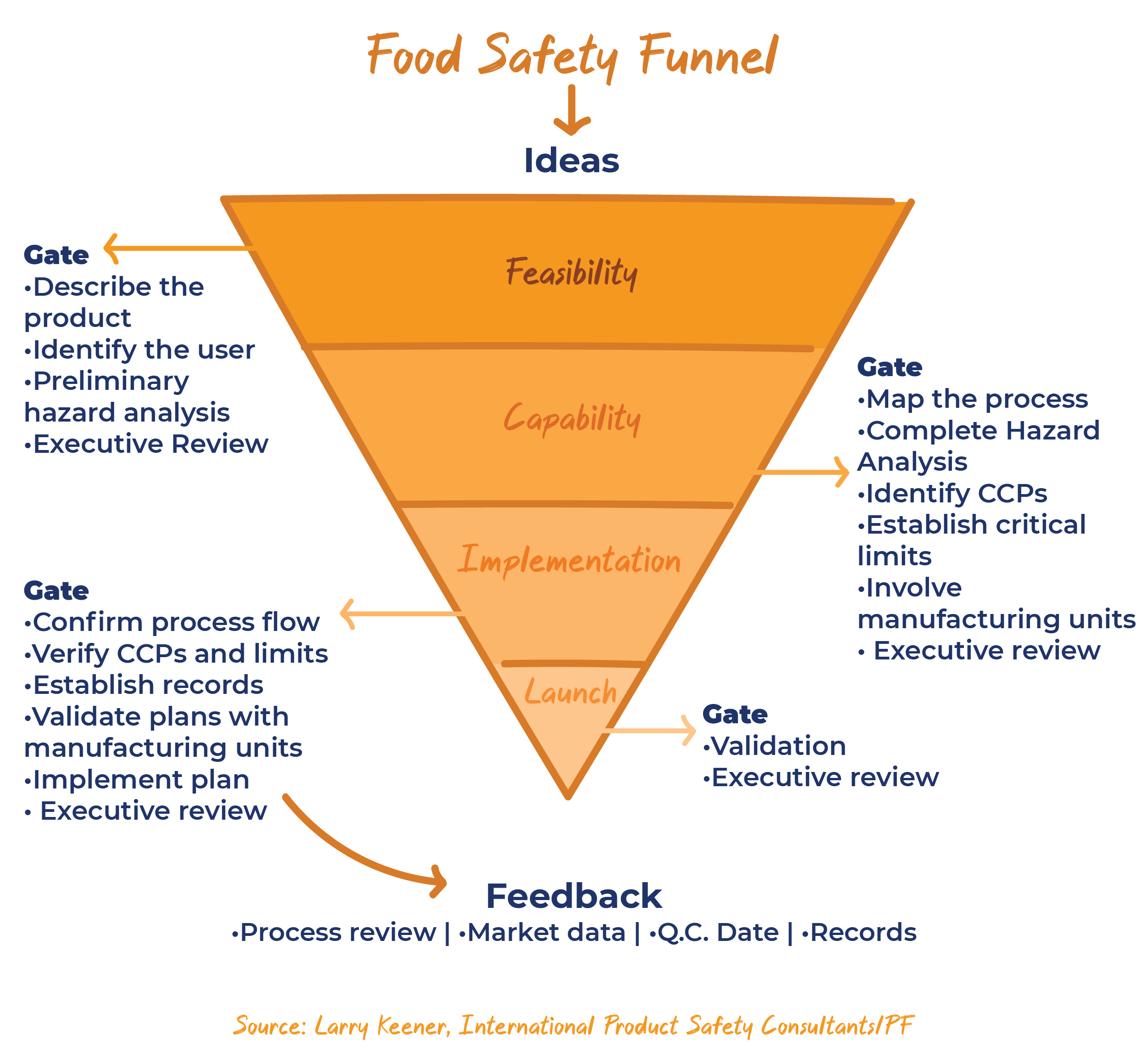

First, the company will form the HACCP Plan’s team. Next, the company will describe the product and identify its intended use; subsequently, the HACCP Plan will explain the production process and draw a diagram flow.

When the diagram flow is ready, all members of the HACCP team must verify the production process on-site to carry out hazard analysis and identify preventive measures as stated in Principle 1 of the HACCP Plan. Then, the critical control points will be determined as stipulated in Principle 2 of the HACCP Plan. Lastly, required limits are established as required by Principle 3 of the HACCP Plan.

Later will be established CCP monitoring requirements to ensure each CCP stays within its limit. Monitoring may require materials or devices to measure or otherwise evaluate the process at CCPs, with this we comply with Principle 4 of the HACCP Plan.

It's essential to establish corrective actions if monitoring determines a CCP is not within the established limits, said limits and their acceptance range are described in Principle 5 of the HACCP Plan. In addition, if a problem occurs, corrective actions must be in place to ensure no public health hazard occurs. Finally, establish effective recordkeeping procedures that document the HACCP system is working correctly. These records comply with Principle 7 of the HACCP Plan and must document CCP monitoring, verification activities, and deviation records.

Another critical step is to establish procedures for verifying that the HACCP system is working correctly. The verification procedures may include reviewing the HACCP plan, CCP records, required limits, and microbial sampling, all these instructions are described in Principle 6 of the HACCP Plan. Don't forget that both plant personnel and FSIS Inspectors, CFIA, Auditors, etc., will conduct verification activities.

Implementing a HACCP Plan demonstrates the commitment to the safety of the products according to the corporate requirements at an international level. It also offers and generates a better position for the company. A HACCP plan grants a reduction in claims, returns, and rejections of products. In addition, it helps increase the training of personnel in charge of production, increases customer satisfaction. It helps decrease the number of audits, reduces investment and related costs, improves the relationship with product safety regulatory authorities, and provides evidence of safe and efficient handling of its products.

At iQKitchen, we care about our clients’ production welfare, so we offer them the design, writing, and implementation of the HACCP Plan to guarantee the quality of their products and reduce production costs.

Dulce Valeria Ramírez Rodríguez

“I am a Senior Writer of HACCP Plans, my area of expertise is the creation of Standard Operating Procedures to validate the various production processes in food and packaging facilities and, thereby, establish third-party Food Safety Plans.”

What is a Preventive Control Plan (PCP) in Canada?

16 infected due to California’s Raw Farms LLC Recall: What You Need to Know to Prevent Outbreaks

Assessing the Effectiveness of Your HACCP Plan: A Year Later

Join our Food

Safety Community!

Stay ahead of the curve by exploring emerging

trends and technologies in food safety.